Digital twin The digital transformation supplied by Field 4.0 has authorized companies to generate electronic twins which have been Digital replicas of processes, production lines, factories and supply chains. A electronic twin is created by pulling facts from IoT sensors, devices, PLCs and other objects connected to the net.

that comes with speedy iterations, rapid fails, and continual Discovering, with groups transforming bundled use circumstances in waves to drive innovation and ongoing refinements.

In depth railroad and telegraph networks allowed for a lot quicker transfer of men and women and ideas. The first glimpse of automation can be traced back to this time frame, with the appearance of the trendy assembly line as we know it these days.

Companies should decide how and where by to speculate in these new technologies and establish which of them may well most effective satisfy their desires. With no total comprehension of the modifications and prospects Market four.0 delivers, corporations danger shedding floor.

This changeover isn't going to just boost upon present strategies, but variations the way businesses produce and distribute solutions entirely whilst making it possible for them to rapidly adapt to unstable current market demands.

—establish talent gaps that needs to be addressed and structure the program infrastructure to address them

As well as the term “revolution” is never to be taken frivolously. On their debut, these innovations — steam, electric power and computers — had been timely innovations that basically adjusted how we labored as well as the production of goods once and for all.

For getting there, 6 Main enablers can Enhance the percentages of accomplishment for your business’s 4IR transformation:

This website takes advantage of cookies to supply expert services underneath the Privateness Plan. You'll be able to specify the disorders for storing and accessing the cookies mechanism with your browser. Learn more. Agree

And a lot more broadly, lighthouses exhibit how 4IR technologies can encourage dependable development in the long run. How? Via action in a few broad locations:

The change to Field four.0 requires a workforce experienced in fields like digital methods, automation and knowledge Examination — all of which keep on to evolve. Researchers have currently recognized a global scarcity of competent staff, like engineers, information experts and operators, with digital skills up-to-par with right now’s tech that hampers widespread adoption.

The early selections produced by Primary Minister Mart Laar about the training course of your nation's economic enhancement led to your institution of what is nowadays known as e-Estonia, one of many worlds most digitally State-of-the-art nations.

The escalating utilization of the lever 4.0 commercial World wide web of issues is referred to as Industry four.0 at Bosch, and customarily in Germany. Apps incorporate devices that could forecast failures and set off maintenance procedures autonomously or self-organised coordination that react to unexpected improvements in creation.

Even if an organization chooses to revamp its machines, workflow disturbances throughout the transition are really possible, introducing to the general cost.

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Jenna Jameson Then & Now!

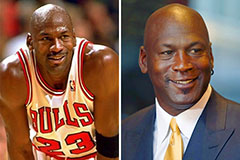

Jenna Jameson Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now!